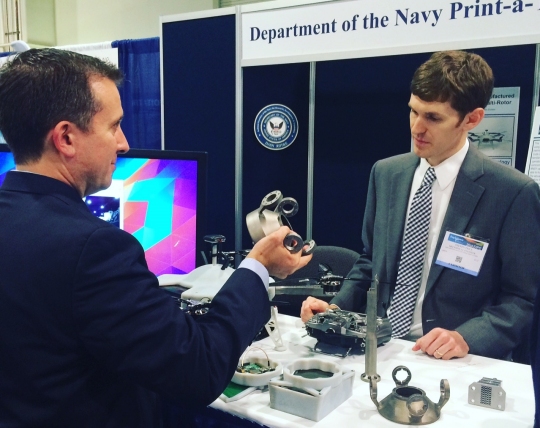

NATIONAL HARBOR, Md. (May 17, 2016)—Navy engineer Steve Price answers an attendee's question about the small additively manufactured modular payload multi-rotor at the 2016 Sea-Air-Space Expo. This low cost, 3D printed, unmanned aerial vehicle is rapidly adaptable to mission requirements and can accept a wide variety of custom payloads. The UAV was one of the exhibits featured at the Navy Additive Manufacturing Showcase in Dahlgren, Va., last month that were selected for display at the Sea-Air-Space Expo. "The volume of creative and innovative ideas made feasible with 3D Printing is astounding," said Lynn Shoppell, a Naval Surface Warfare Center Dahlgren Division physicist after the Dahlgren showcase. "The exhibitors demonstrated that their concepts for increased technical capabilities, rapid prototyping, improved logistics operations, and cost reduction initiatives are achievable with 3D Printing. Participants also experimented with additive manufacturing technology research and development." (U.S. Navy photo/released)

NATIONAL HARBOR, Md. (May 17, 2016)—Navy engineer Steve Price answers an attendee's question about the small additively manufactured modular payload multi-rotor at the 2016 Sea-Air-Space Expo. This low cost, 3D printed, unmanned aerial vehicle is rapidly adaptable to mission requirements and can accept a wide variety of custom payloads. The UAV was one of the exhibits featured at the Navy Additive Manufacturing Showcase in Dahlgren, Va., last month that were selected for display at the Sea-Air-Space Expo. "The volume of creative and innovative ideas made feasible with 3D Printing is astounding," said Lynn Shoppell, a Naval Surface Warfare Center Dahlgren Division physicist after the Dahlgren showcase. "The exhibitors demonstrated that their concepts for increased technical capabilities, rapid prototyping, improved logistics operations, and cost reduction initiatives are achievable with 3D Printing. Participants also experimented with additive manufacturing technology research and development." (U.S. Navy photo/released)DAHLGREN, Va. (May 18, 2016)—Is it possible to produce parts and equipment from scratch for Sailors—aboard ships and on demand?

Can the Navy rush deliver parts and high-tech gear such as customized unmanned systems, avionics components, and improvised explosive device detectors to its warfighters?

"Yes we can," say Navy officials and when Additive Manufacturing—also known as 3D Printing—fully hits the Fleet, Sailors could receive their orders within a substantially reduced time frame.

Remarkably, Sailors and Marines are already inventing new products, expanding the realm of possibilities made real by 3D printing while saving time, resources, and money.

"Additive manufacturing will fundamentally change how we think, how we do business, the cost variable, and how we make decisions," Dr. John Burrow, Deputy Assistant Secretary of the Navy for Research, Development, Test and Evaluation told a gathering of 3D Printing exhibitors and visitors at the Department of the Navy Additive Manufacturing Showcase April 20. "I think you are about to see its operational and technical potential literally explode off the map."

As Burrow and Navy officials look at that map, they envision a future with 3D printers forward-deployed with Marines and installed aboard warships as well as shore-based commands.

In fact, Navy Supply Command is anticipating a paradigm shift that will enable delivery of parts and equipment "just in time" to Sailors.

This shift to integrate 3D Printing into the Navy's supply strategy will ensure that no request for a manufactured item will be left behind, according to Capt. Armen Kurdian, Director of Engineering and Product Support for Navy Supply Command.

What's more, Sailors without a 3D printer or unable to make a product won't have to look far for support. Their command supply officers will be able to special order parts and equipment for rapid production via 3D Printing.

"Additive manufacturing could bring about revolutionary changes to the Navy Supply System, with an associated paradigm shift from the current order and stocking system to implementation of just-in-time inventory," said Kurdian, after the event, hosted by Naval Surface Warfare Center (NSWC) Dahlgren Division. "It has the potential to move the point of manufacture for hundreds of components and parts closer to the point of demand."

In many cases, the waiting time for an order could be reduced from months or weeks to days or hours.

Kurdian, Burrow and more than 100 visitors perusing the exhibits at the University of Mary Washington Dahlgren campus were clearly struck by the reality of 3D Printing's potential impact to the Fleet.

"The volume of creative and innovative ideas made feasible with 3D Printing is astounding," said Lynn Shoppell, an NSWC Dahlgren Division physicist who coordinated the showcase. "The exhibitors demonstrated that their concepts for increased technical capabilities, rapid prototyping, improved logistics operations, and cost reduction initiatives are achievable with 3D Printing. Participants also experimented with additive manufacturing technology research and development."

From a vantage point on stage during his keynote speech, Burrow could see 25 additive manufactured projects rapidly 3D printed by government employees to solve problems, reduce costs, reduce risk, and improve technical capabilities for the warfighter.

Suddenly, he pointed to one project in the back of the auditorium.

"You can't put that on a ship or a submarine—it's for training," said Burrow regarding the Globe Valve Training Aid, 3D manufactured by NSWC Dahlgren Division engineers based at Combat Direction Systems Activity in Dam Neck, Va. The one-inch manual primary globe valve was built for classroom training at Norfolk Naval Ship Yard. The valve mock-up is being used to familiarize engineers and mechanics with valve operation and repair procedures.

"It's significant because this same tool is used in a training classroom to give Sailors or Marines an opportunity to tear it apart and put it back together," said Burrow. "The original system costs $50,000 but they built it for $500. Identical, and that's significant. Start looking at these price differentials. They are substantial."

Burrow sponsored the event to explore innovative applications of additive manufacturing that benefit the warfighter and to highlight its impact throughout program lifecycles from early concepts, into component and system testing, and sustainment.

The Navy still has crucial engineering, business, and legal questions to answer, however, before it can fully take advantage of additive manufacturing capabilities. For example, how will acquisition program managers know that parts produced via 3D printing match the specifications of the same parts produced conventionally? How will supply officers apply data rights and intellectual property laws? How will they handle orders and billing?

"If we don't manage and implement the business side of additive manufacturing properly, we could fail to realize the full weight of the benefits it can bring to the Department of Defense," cautioned Kurdian. "We will need to develop new contracting strategies to exploit on demand or even automated IDIQ (indefinite order, indefinite quantity] so that a Fleet user could put in a demand signal for a particular component. An order would be transmitted through the supply system to the most suitable geographic location where it could conceivably get a 3-D machine printing that part without any human interaction from the moment the demand signal is sent."

Exhibitors showcasing additive manufacturing projects represented Naval Air Systems Command, Naval Research Laboratory, NSWC Carderock, NSWC Indian Head EODTD, NSWC Panama City, NSWC Dahlgren, Naval Undersea Warfare Center (NUWC) Keyport, NUWC Newport, Johns Hopkins University Applied Physics Laboratory, Pennsylvania State University Applied Research Laboratory, and Walter Reed Medical Facility Department of Radiology.

Each participating organization developed, designed, and fabricated components or complete systems using additive manufacturing to directly benefit the warfighter.

In addition to the Globe Valve Training Aide, 3D projects on exhibit included:

• Meso-scale Robotic Locomotion Initiative.

• Waterjets Utilized on Model-Scale Test Platforms for Hydrodynamic Testing and Evaluation.

• Hierarchial and Multiscale Topology Optimization for On-Demand Hand Tools.

• Tunable Metamaterial Hulls for Acoustically Cloakable Uninhabited Underwater Vehicles.

• MK29 Helmet Modifications.

• Medium Girder Bridge Model Training Aid sets.

• Reinventing Unmanned Systems and System Performance Metrology

Selected submissions from the showcase at Dahlgren were on exhibit at the Navy League's 2016 Sea-Air-Space Exposition from May 16-18, 2016.

CHINA LAKE, Calif.—Dr. John Burrow gets behind the wheel of a driverless, Ford F-350 truck with software integrated by the Applied Manufacturing Technology Department at Naval Air Warfare Center Weapons Division China Lake. The department helps modify the trucks to pull targets during weapons testing. "Additive manufacturing will fundamentally change how we think, how we do business, the cost variable, and how we make decisions," Burrow—Deputy Assistant Secretary of the Navy for Research, Development, Test and Evaluation—told 3D Printing exhibitors and visitors at the Navy Additive Manufacturing Showcase April 20, 2016. "I think you are about to see its operational and technical potential literally explode off the map." (U.S. Navy photo/released)

CHINA LAKE, Calif.—Dr. John Burrow gets behind the wheel of a driverless, Ford F-350 truck with software integrated by the Applied Manufacturing Technology Department at Naval Air Warfare Center Weapons Division China Lake. The department helps modify the trucks to pull targets during weapons testing. "Additive manufacturing will fundamentally change how we think, how we do business, the cost variable, and how we make decisions," Burrow—Deputy Assistant Secretary of the Navy for Research, Development, Test and Evaluation—told 3D Printing exhibitors and visitors at the Navy Additive Manufacturing Showcase April 20, 2016. "I think you are about to see its operational and technical potential literally explode off the map." (U.S. Navy photo/released)